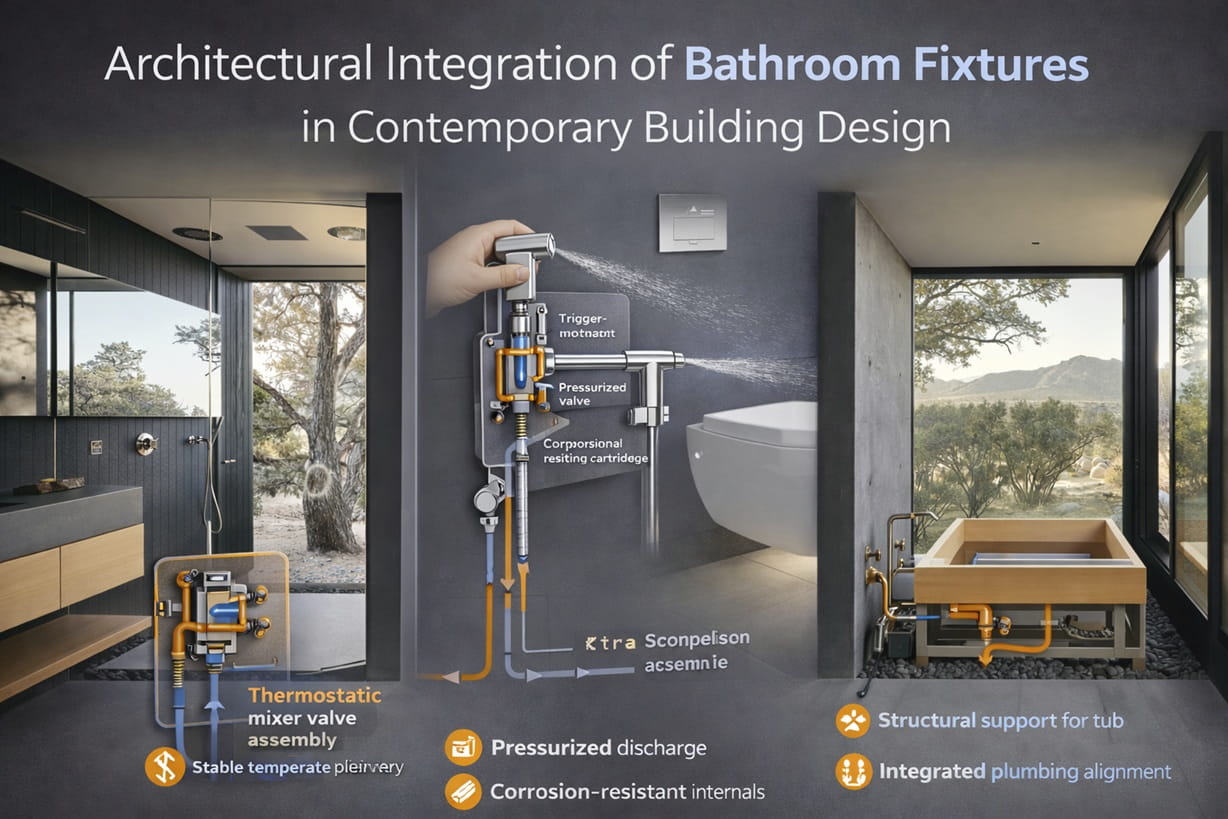

Architectural Integration of Bathroom Fixtures in Building Systems Design

Bathroom fixtures are not standalone consumer products; they are integrated terminal components of complex, multi-disciplinary building systems involving plumbing engineering, hydraulic performance, structural coordination, architectural ergonomics, infection control, and lifecycle asset management.

Within the Architecture, Engineering, and Construction industry, fixtures must be specified and integrated based on quantifiable performance criteria including hydraulic loading, fixture unit calculations, material compatibility, code compliance, serviceability accessibility, and long-term reliability.

Fixtures serve as the final interface between building occupants and engineered plumbing infrastructure. Improper architectural integration results in hydraulic imbalance, pressure instability, trap seal depletion, accelerated material degradation, maintenance inaccessibility, and user dissatisfaction.

Authoritative Reference

International Plumbing Code Uniform Plumbing Code ASHRAE HVAC Applications HandbookClassification of Bathroom Fixtures Within Architectural and Plumbing Systems

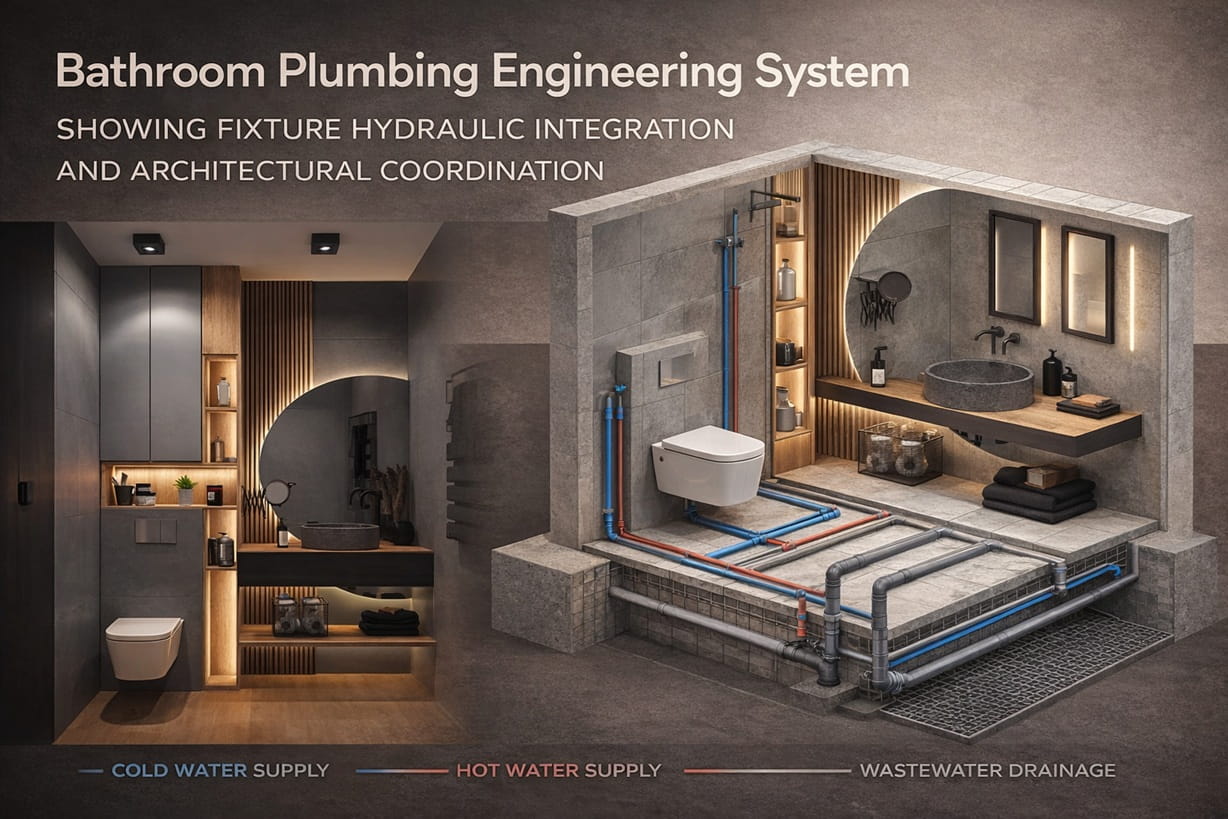

Bathroom fixtures are classified as terminal plumbing devices connected to water supply and sanitary drainage systems. Architectural integration requires classification based on hydraulic demand, discharge characteristics, mounting methodology, and functional application.

Fixture Classification Based on Hydraulic Demand Characteristics

Fixtures are categorized based on probabilistic water demand modeling using Fixture Units as defined by IPC Chapter 6 and UPC Chapter 6.

Water Supply Fixture Units

Water Supply Fixture Units quantify probable peak demand based on simultaneous usage probability.

| Fixture | WSFU Public | WSFU Private |

|---|---|---|

| Lavatory faucet | 0.5 | 1.0 |

| Shower | 1.0 | 2.0 |

| Bathtub | 1.4 | 2.0 |

| Water closet flush tank | 2.5 | 2.5 |

| Water closet flush valve | 10.0 | N/A |

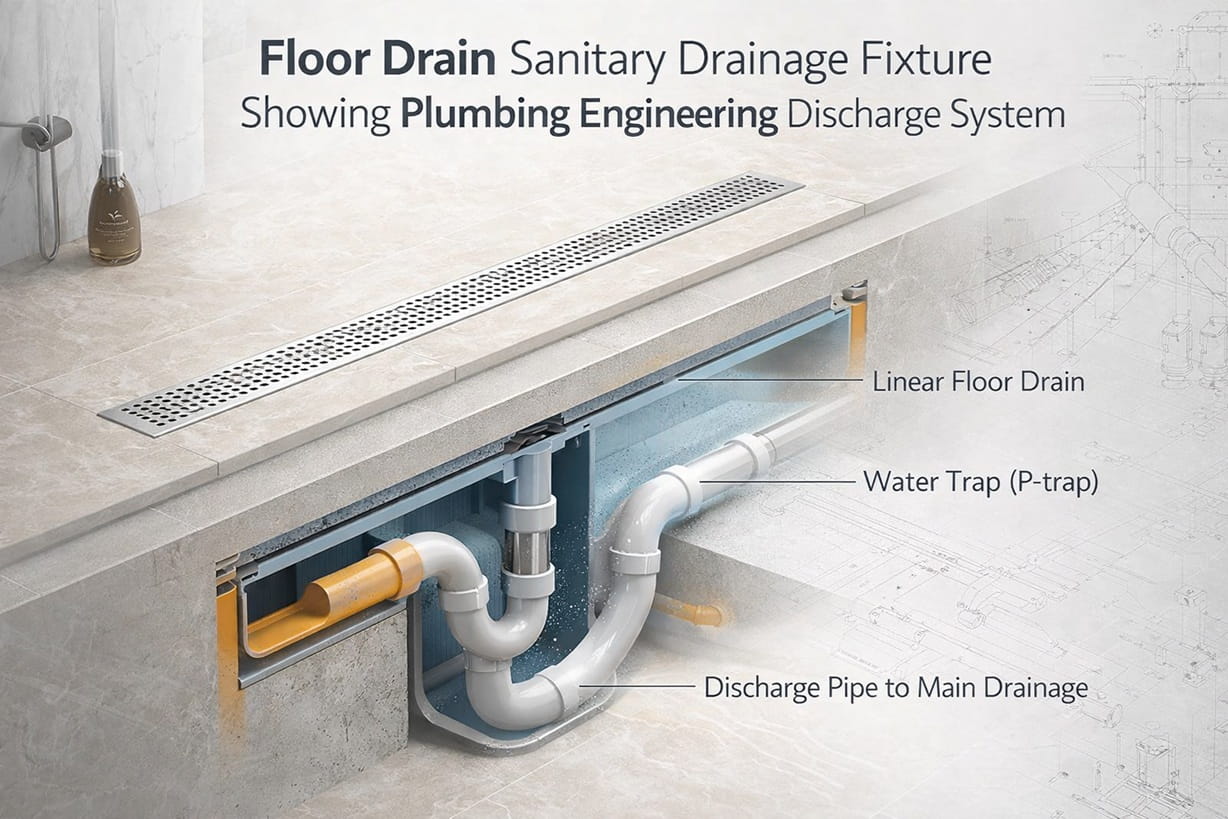

Drainage Fixture Units

Drainage Fixture Units quantify discharge loading imposed on sanitary drainage systems.

| Fixture | DFU |

|---|---|

| Lavatory | 1 |

| Shower | 2 |

| Floor drain | 2 |

| Water closet public | 4 |

| Bathtub | 2 |

Fixture Classification Based on Functional System Integration

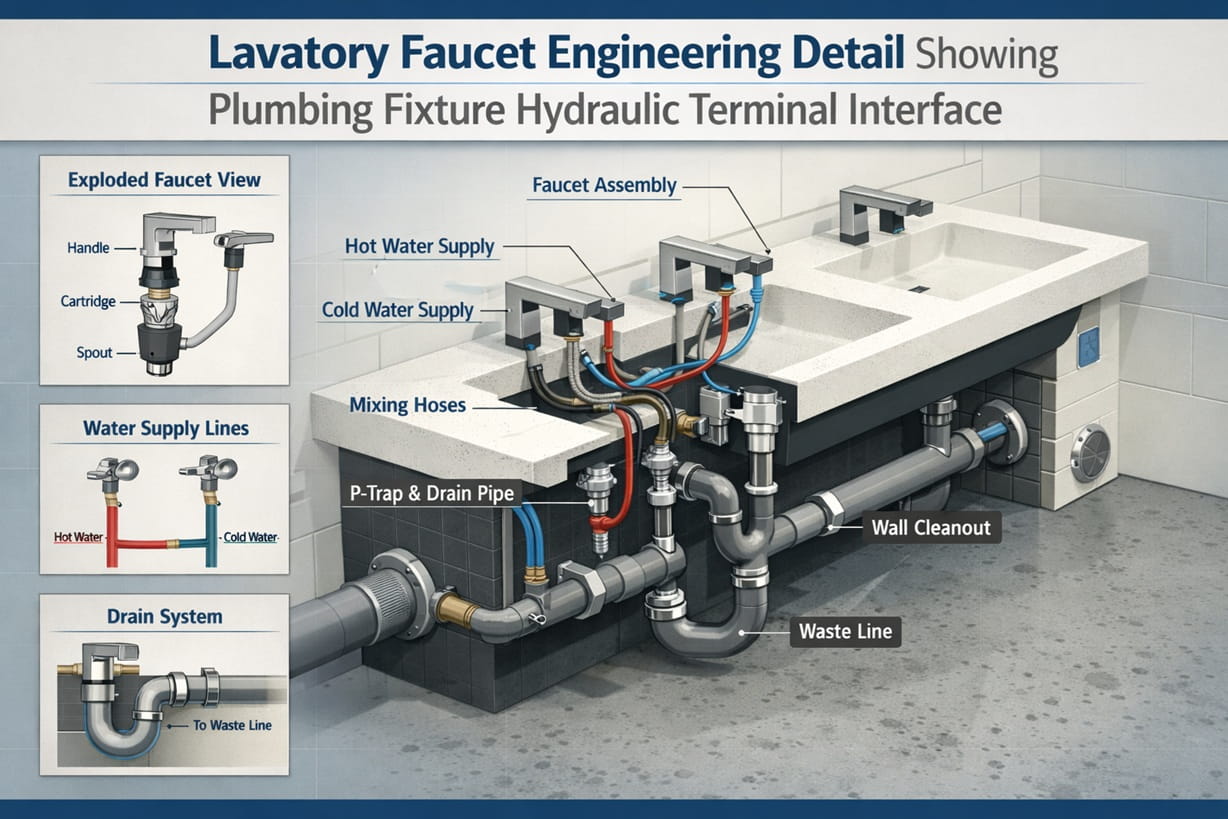

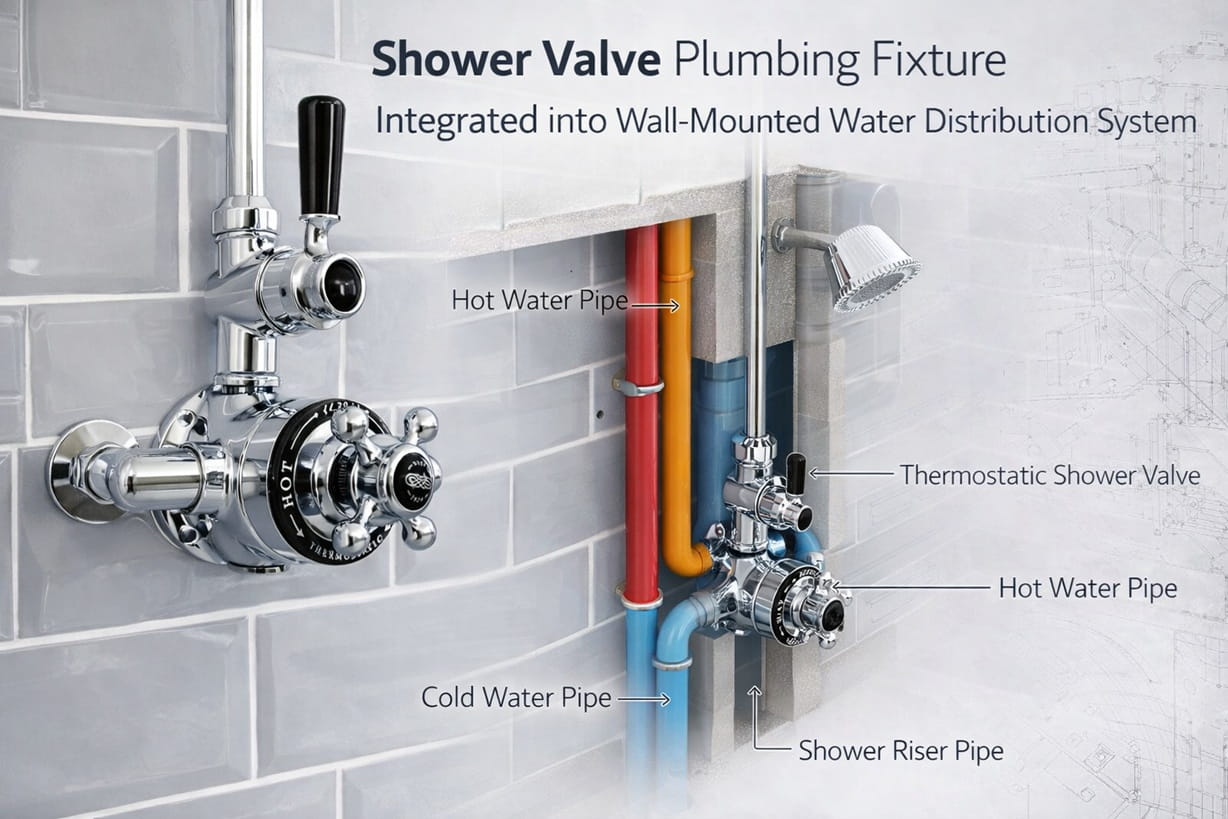

Fixtures are integrated into domestic water distribution systems including lavatory faucets, bathtub fillers, shower valves, bidets, and sensor-operated faucets. These fixtures function as terminal flow control devices regulating discharge volume, temperature stability, and user interface performance.

ASME Plumbing Supply Fittings Standard

Sanitary drainage terminal fixtures include water closets, urinals, floor drains, sink drains, and bathtub drains. These fixtures serve as hydraulic discharge interfaces connected to gravity drainage networks designed to safely transport wastewater.

ASME Ceramic Plumbing Fixture StandardArchitectural Design Considerations for Fixture Integration

Fixture integration must be evaluated across architectural coordination, hydraulic performance, structural load transfer, and maintenance accessibility dimensions.

Architectural Spatial Coordination Requirements

Architectural drawings coordinate fixture placement relative to structural framing systems, wall assemblies, mechanical duct routing, plumbing risers, and accessibility clearance requirements. These coordination requirements ensure safe installation and operational access throughout the building lifecycle.

ADA Accessibility Design StandardsMounting Heights and Anthropometric Coordination

| Fixture | Mounting Height |

|---|---|

| Lavatory rim | 813–864 mm above finished floor |

| Urinal rim | 432–457 mm above finished floor |

| Shower valve | 1016–1219 mm above finished floor |

| Toilet seat height | 406–432 mm above finished floor |

Accessibility and Barrier-Free Design Constraints

Lavatory fixtures require minimum forward clearance of 762 mm and knee clearance of 685 mm minimum to ensure accessibility compliance. Water closets require minimum side clearance of 457 mm from wall centerline to provide safe and usable spatial accommodation.

ADA Accessibility Compliance ResourceStructural Integration Requirements

Fixture loads must be supported structurally using engineered carrier systems, backing plates, or reinforced wall assemblies designed to transfer loads safely into the structural framework.

Wall-Mounted Fixture Load Transfer Mechanics

Wall-mounted water closet carriers typically support minimum load ratings of 500 kilograms, while lavatory carrier systems support load ranges between 150 and 300 kilograms depending on fixture configuration and structural mounting design.

ASME Fixture Carrier Support StandardHydraulic Performance Considerations in Architectural Fixture Selection

Hydraulic performance determines operational reliability, pressure stability, user satisfaction, and regulatory compliance.

Flow Rate Engineering Constraints

Lavatory faucets operate with maximum flow rates of 1.5 gallons per minute. Showerheads operate at maximum flow rates of 2.5 gallons per minute. Water closets operate at maximum discharge volumes of 1.6 gallons per flush.

Energy Policy Act Water Efficiency StandardPressure and Flow Stability Requirements

Operating pressure ranges between 20 psi minimum and 80 psi maximum ensure safe and stable fixture performance.

International Plumbing Code Pressure RequirementsPressure Loss and Hydraulic Friction Considerations

Fixture flow performance is influenced by pipe diameter, pipe surface roughness, fitting losses, and valve flow restrictions. Hydraulic friction losses are calculated using the Darcy-Weisbach equation to ensure accurate hydraulic design.

Crane Fluid Flow Engineering ReferenceMaterial Science Considerations in Architectural Fixture Specification

Vitreous China Fixtures

Vitreous china fixtures provide high compressive strength, non-porous surfaces, chemical resistance, and service life exceeding fifty years.

Ceramic Engineering Material ReferenceBrass and Bronze Valve Components

Brass and bronze components provide corrosion resistance, machinability, and high pressure tolerance suitable for hydraulic systems.

ASTM Brass Material StandardStainless Steel Fixtures

Stainless steel grades AISI 304 and AISI 316 provide corrosion resistance, hygienic compatibility, and structural durability.

Nickel Institute Material Science ResourceCoordination Between Architectural and Plumbing Engineering Disciplines

BIM Integration for Fixture Coordination

Building Information Modeling enables clash detection, spatial coordination verification, maintenance accessibility planning, and hydraulic system modeling.

National BIM StandardClash Detection and Spatial Conflict Resolution

Common coordination conflicts occur between fixture carriers and structural beams, drainage pipes and structural slabs, and valve access clearances within architectural wall assemblies.

Autodesk BIM Engineering GuideLifecycle Performance and Maintainability Considerations

| Fixture | Service Life |

|---|---|

| Ceramic fixtures | More than 50 years |

| Faucets | 10 to 20 years |

| Flush valves | 10 to 15 years |

| Sensor faucets | 5 to 10 years |

Maintenance Accessibility Requirements

Fixtures must provide access to shutoff valves, trap assemblies, flush valve mechanisms, and sensor electronics to ensure maintainability.

Facility Maintenance StandardsInfection Control and Hygienic Architectural Design Considerations

Touchless Fixture Integration

Sensor-operated fixtures reduce microbial transmission and improve hygiene performance in architectural environments.

CDC Healthcare Plumbing GuidelinesSurface Material Hygiene Performance

Stainless steel and vitreous china provide reduced microbial adhesion compared to polymeric surfaces.

NIH Healthcare Surface StudyConclusion: Role of Fixtures in Architectural Systems Engineering

Bathroom fixtures represent critical terminal components requiring integrated design across architectural, plumbing, structural, and maintenance disciplines. Proper specification ensures hydraulic stability, compliance, structural safety, accessibility, and lifecycle reliability.

Fixtures function as engineered interfaces within complex building infrastructure networks governed by performance standards and multidisciplinary coordination.